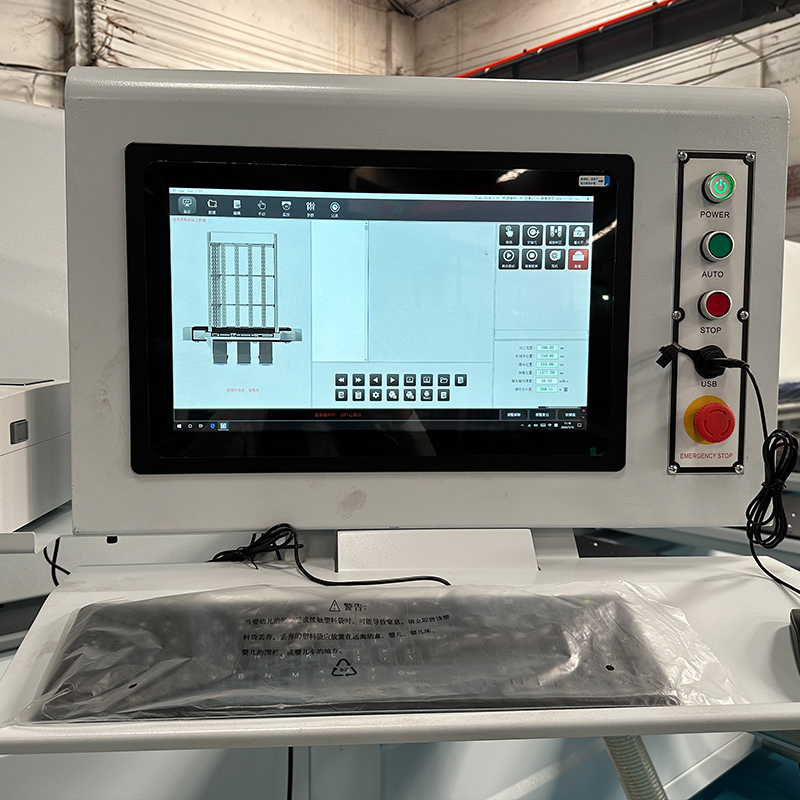

Computer industrial control computer: including

Printer: optional

Optimization software: optional

Side leaning: optional

Sawing length/width: 3800mm

Maximum sawing thickness: 120mm

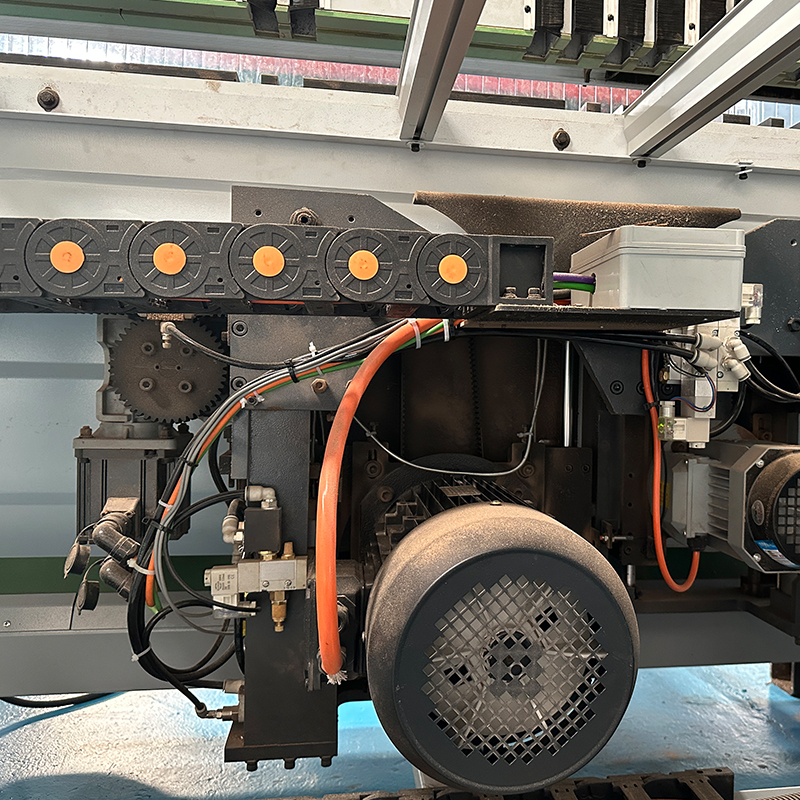

Main saw blade diameter: Φ 400-450mm

Main saw shaft diameter: Φ 75mm

Secondary saw blade diameter: Φ 200mm

Secondary saw shaft diameter: Φ 50mm

Main saw speed/frequency converter speed regulation: 4100r/min

Secondary saw speed/frequency converter speed regulation: 6100r/min

Saw seat forward speed: 100m/min (adjustable)

Saw seat retreat speed: 120m/min (adjustable)

Main saw motor: 18.5kw

Auxiliary saw motor: 2.2kw

Saw seat drive motor: 2.0kw (Envision servo)

Feeding positioning motor: 2.0kw (Infineon servo)

High pressure fan (2): 4kw, 2.2kw

Total power: 31kw

Automatic feeding speed: 100/min (adjustable)

Using air pressure: 5-8kg/cm ²

Workbench ground clearance: 950mm

Mechanical Claw Hands: 10 (Double Claw)

Machine appearance: 6300 * 7500 * 1900mm

Categories: Computer Panel Saw KH Series Cutting Height 120mm

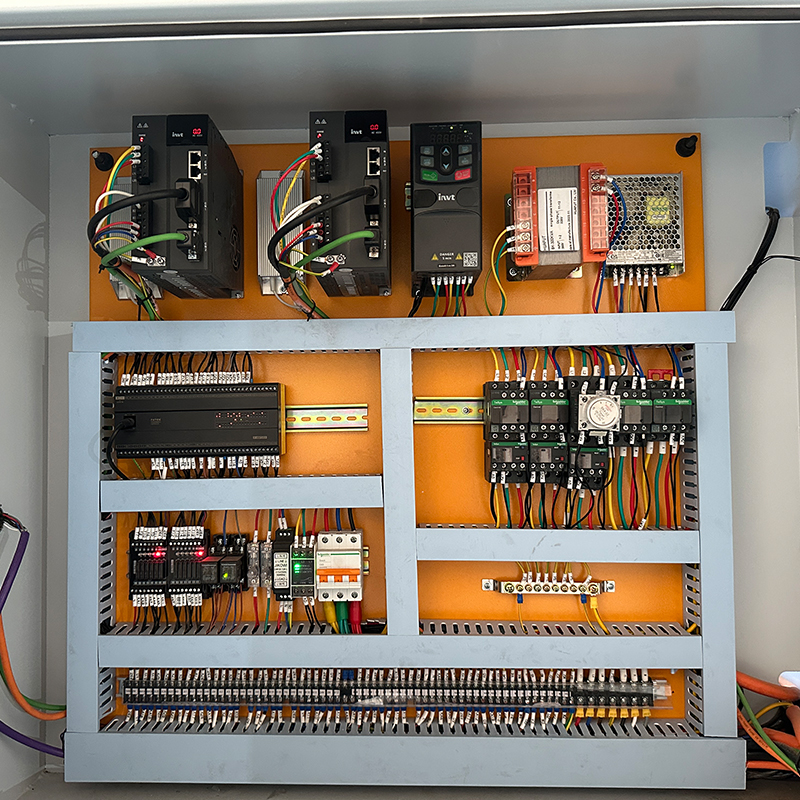

①. The electrical system adopts “Taiwan Yonghong System”, “Envision Servo and Inverter”, “Schneider Electric”, “Taiwan

Famous international and domestic brands such as “Wan Ya De Rui Dong Electromagnetic Valve” make machine operation more stable;

②. Precision frame precision and strict processing, precise and reliable. No need for electronic ruler positioning compensation, accuracy is not affected by the surrounding environment

The influence of environmental and magnetic fields, as well as safety and stability, ensures sawing accuracy without the need for deliberate maintenance;

③. By using high-quality flexible robot specific cables, the service life is extended to a greater extent;

④. After welding the rack, a dual treatment of electromagnetic aging and annealing aging is adopted, thus achieving the goal of the rack never being damaged

The durable effect of deformation.

Copyright © 2025 Foshan Weiqun Machinery Co., Ltd. All Rights Reserved.