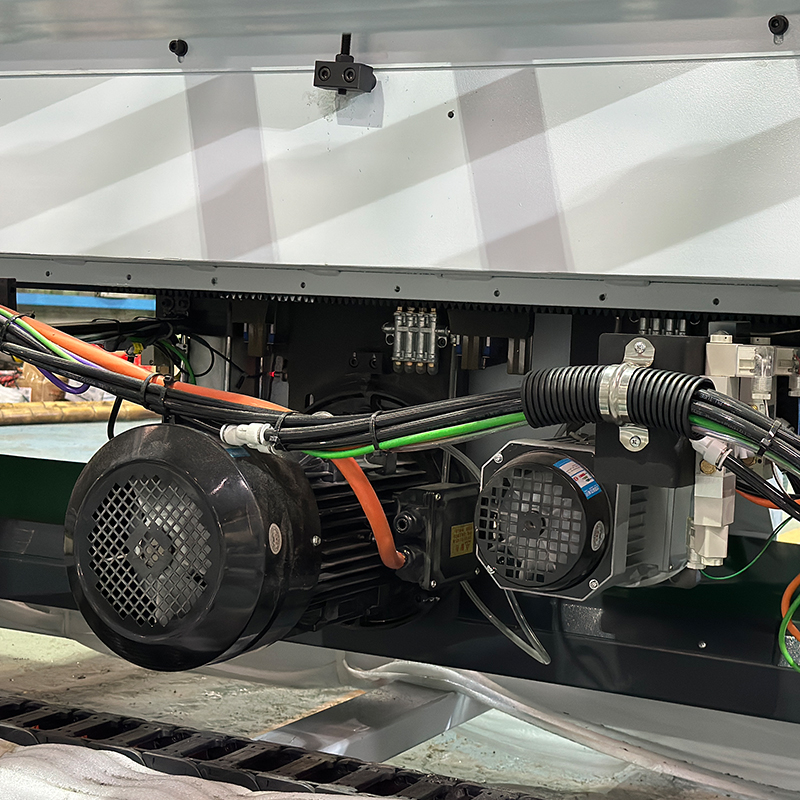

Main saw power: 16.5kw

Auxiliary saw motor power: 2.2kw

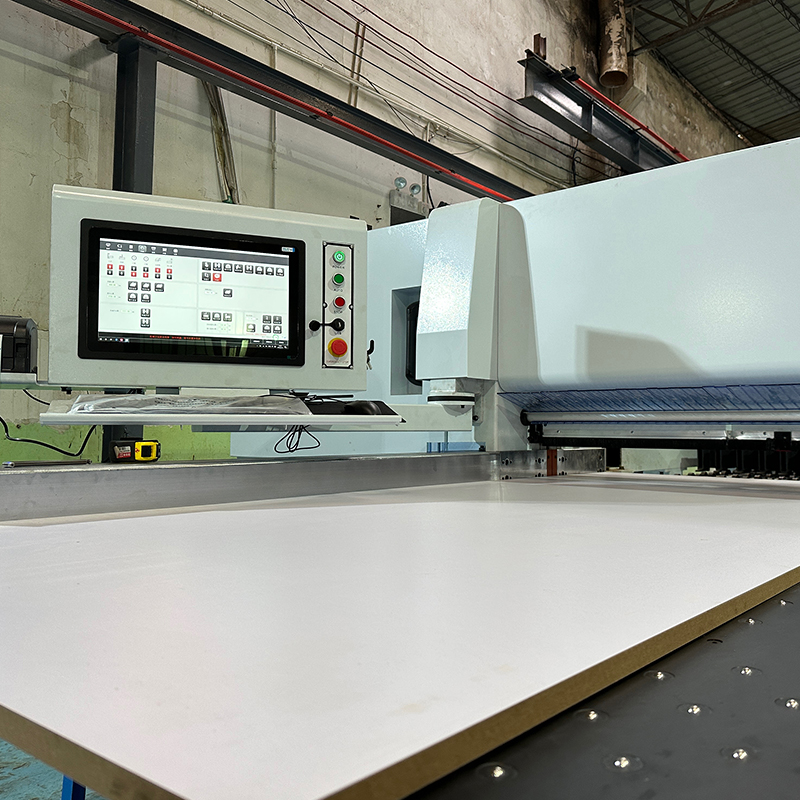

Maximum sawing length: 4500mm

Maximum sawing thickness: 100mm

Maximum sawing width: 4500mm

Minimum board size for horizontal cutting: 5mm

Minimum vertical cutting board size: 40mm

Positioning method: automatic

Servo positioning accuracy: 0.02mm

Sawing accuracy: ± 0.1mm

Main saw blade outer diameter: 360mm-400mm

Main saw blade inner diameter: 75mm

Main saw speed/frequency converter speed regulation: 4800r/min

Traction motor power (rack drive): 2.0KW

Mechanical arm servo motor: 2.0kw

Side mounted motor: 0.55kw

Sawing speed: 0-100 meters per minute

Return speed: 120 meters per minute

High pressure fan: 4KW 2.2KW (two)

Air pressure: 0.6-0.8MPA

Specification of air flotation table: 1750 * 540mm

Machine tool dimensions: 7000 * 7820 * 2000mm

Total power: 29KW

Display screen: 19 inches

Categories: Computer Panel Saw KS Series Cut Height 100mm

Advantages of electronic panel saw and CNC panel saw: 1. The saw machine drive system adopts servo control and gear rack transmission, with stable operation and a cutting speed of up to 85m/min. According to the different cutting widths, the automatic positioning of the cutting stroke is achieved, reducing idle walking time and improving work efficiency. The workbench adopts a pneumatic floating ball table, which can effectively prevent scraping and make it more convenient to move the board. 2. The main and auxiliary saws adopt independent lifting control systems. The height of the main saw can be automatically adjusted according to the cutting thickness to achieve good cutting effect. 3. Quick disassembly device for saw blades: The saw blades can be quickly disassembled and installed, effectively reducing the burden on workers. 4. Saw blade protection: The saw blade lifting adopts a special pneumatic control structure to achieve the self-supporting function of the saw blade lifting, preventing the saw blade from suddenly falling off due to accidents (such as power outages) when replacing the saw blade. 5. Automatic positioning of saw blade: The main saw and auxiliary saw are independently raised and lowered. The main saw can automatically adjust the lifting height according to the cutting thickness, achieving good cutting effect. 6. Automatic positioning for beam lifting: During a single sawing cycle, the lifting distance is adjusted according to the thickness of the board, reducing the cylinder stroke and increasing sawing efficiency by a quarter.

Copyright © 2025 Foshan Weiqun Machinery Co., Ltd. All Rights Reserved.